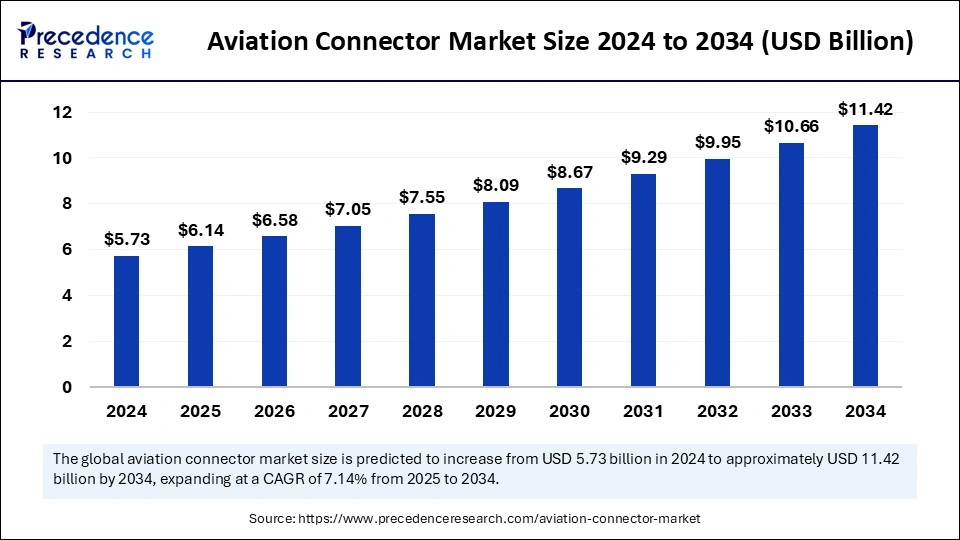

The global aviation connector market size was valued at USD 5.73 billion in 2024 and is expected to cross around USD 11.42 billion by 2034, growing at a CAGR of 7.14% from 2025 to 2034.

Aviation Connector Market Key Points

-

In 2024, North America secured the largest market share at 36%.

-

The Asia Pacific region is anticipated to grow at the fastest CAGR of 10% in the coming years.

-

The fiber optic connectors segment emerged as the dominant type, holding a 31% market share in 2024.

-

The high-power connectors segment is expected to expand at the fastest pace over the forecast period.

-

The commercial aircraft segment was the leading category by aircraft type in 2024.

-

The business and general aviation aircraft segment is likely to witness considerable growth in the forecast period.

-

The engines segment accounted for the highest market share by application in 2024.

-

The in-flight entertainment (IFE) systems segment is set to grow at the highest CAGR in the upcoming years.

Get a Free Sample Copy of the Report@ https://www.precedenceresearch.com/sample/5769

Role of AI in the Aviation Connector Market

Artificial Intelligence (AI) is transforming the aviation connector market by enhancing manufacturing efficiency, improving predictive maintenance, and optimizing performance in aircraft systems. AI-driven automation in connector manufacturing helps streamline production, ensuring higher precision and reduced defects. Machine learning algorithms analyze vast datasets to optimize connector designs for better durability, conductivity, and resistance to harsh environmental conditions. This leads to the development of next-generation connectors that can withstand extreme temperatures, vibrations, and electromagnetic interference, making them more reliable for critical aviation applications.

AI also plays a crucial role in predictive maintenance by monitoring connector performance in real-time. Smart sensors and AI-driven analytics detect early signs of wear and potential failures, allowing airlines to perform proactive maintenance and reduce the risk of in-flight malfunctions. This enhances aircraft safety and minimizes downtime. Additionally, AI-powered quality control systems use image recognition and anomaly detection to ensure only high-quality connectors are used in aircraft assembly. As AI technology continues to advance, its integration in the aviation connector market is expected to further improve efficiency, reliability, and overall aircraft performance.

Aviation Connector: Overview and Key Insights

Overview

Aviation connectors are specialized electrical connectors designed for use in aircraft systems, ensuring reliable signal and power transmission in harsh environments. These connectors are built to withstand extreme temperatures, vibrations, and electromagnetic interference while maintaining high performance in aerospace applications. They are essential components in avionics, flight control systems, in-flight entertainment, and communication networks.

Key Features of Aviation Connectors

-

High Durability – Resistant to extreme temperatures, pressure changes, and mechanical stress.

-

Lightweight & Compact – Designed to reduce aircraft weight while ensuring high efficiency.

-

EMI & RF Shielding – Protects against electromagnetic interference for uninterrupted performance.

-

Sealed & Corrosion-Resistant – Offers protection against moisture, chemicals, and environmental factors.

-

High-Speed Data Transmission – Supports modern aircraft systems with fast and reliable connectivity.

Types of Aviation Connectors

-

Fiber Optic Connectors – Used in high-speed data transmission for avionics and communication.

-

High-Power Connectors – Designed for electrical power distribution in aircraft systems.

-

RF Connectors – Used for wireless communication and radar systems.

-

Circular Connectors – Commonly used in avionics and flight control applications.

-

Rectangular Connectors – Provide high-density connections for complex aircraft systems.

Applications of Aviation Connectors

-

Avionics Systems – Used in navigation, flight control, and cockpit instrumentation.

-

Engines & Power Distribution – Ensure seamless power transmission to aircraft components.

-

In-Flight Entertainment & Connectivity – Supports passenger screens, Wi-Fi, and communication systems.

-

Radar & Communication Systems – Essential for air traffic control and military applications.

-

Cabin Lighting & Safety Systems – Integrated into aircraft lighting, emergency systems, and sensors.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 11.42 Billion |

| Market Size in 2025 | USD 6.14 Billion |

| Market Size in 2024 | USD 5.73 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 7.14% |

| Dominated Region | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application , Aircraft, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

The growing demand for more efficient and reliable aircraft systems is driving the aviation connector market. With the increasing adoption of fly-by-wire technology, modern avionics, and advanced communication systems, the need for high-performance connectors has grown significantly. Additionally, advancements in military aviation, including next-generation fighter jets and unmanned aerial vehicles (UAVs), are further boosting demand for durable and lightweight connectors.

Opportunities

The transition to electric aircraft and advancements in hybrid propulsion systems present lucrative opportunities for the aviation connector market. As aircraft manufacturers focus on sustainability and energy efficiency, there is a rising need for connectors that can handle high voltages while minimizing weight. Additionally, the increasing use of cloud-based monitoring systems in aviation is opening doors for innovative, data-driven connector solutions with self-diagnostic capabilities.

Challenges

The aviation industry operates under strict regulatory frameworks, making compliance a major challenge for connector manufacturers. Developing connectors that meet safety, durability, and electromagnetic interference (EMI) shielding requirements adds to production complexity and costs. Moreover, market competition among key players and the continuous demand for miniaturization without compromising performance add additional technical challenges.

Regional Insights

The aviation connector market in North America remains dominant due to a well-established aerospace industry, a high number of aircraft manufacturers, and defense sector investments. Europe is also a key market, with demand driven by leading aircraft manufacturers such as Airbus and increasing military spending. Asia Pacific is growing rapidly, fueled by increased air passenger traffic, expanding airline fleets, and regional government support for aerospace development, particularly in China and India.

Aviation Connector Market Companies

- Amphenol Corporation

- TE Connectivity

- Eaton

- Smiths Group plc

- Radiall

- ITT Inc.

- Bel Fuse Inc.

- IEH Corporation

- Apollo Aerospace Components

- Rosenberger Hochfrequenztechnik GmbH & Co. KG

Segments Covered in the Report

By Type

- PCB Connectors

- Fiber Optic Connectors

- High-power Connectors

- High-speed Connectors

- RF Connectors

- Others

By Aircraft

- Commercial Aircraft

- Military Aircraft

- Business and General Aviation Aircraft

By Application

- Avionics

- Engines

- Power Distribution and Electrical Systems

- In-Flight Entertainment

- Cabin Systems

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Middle East & Africa

- Latin America

Also Read: Arbitrary Waveform Generator Market

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/