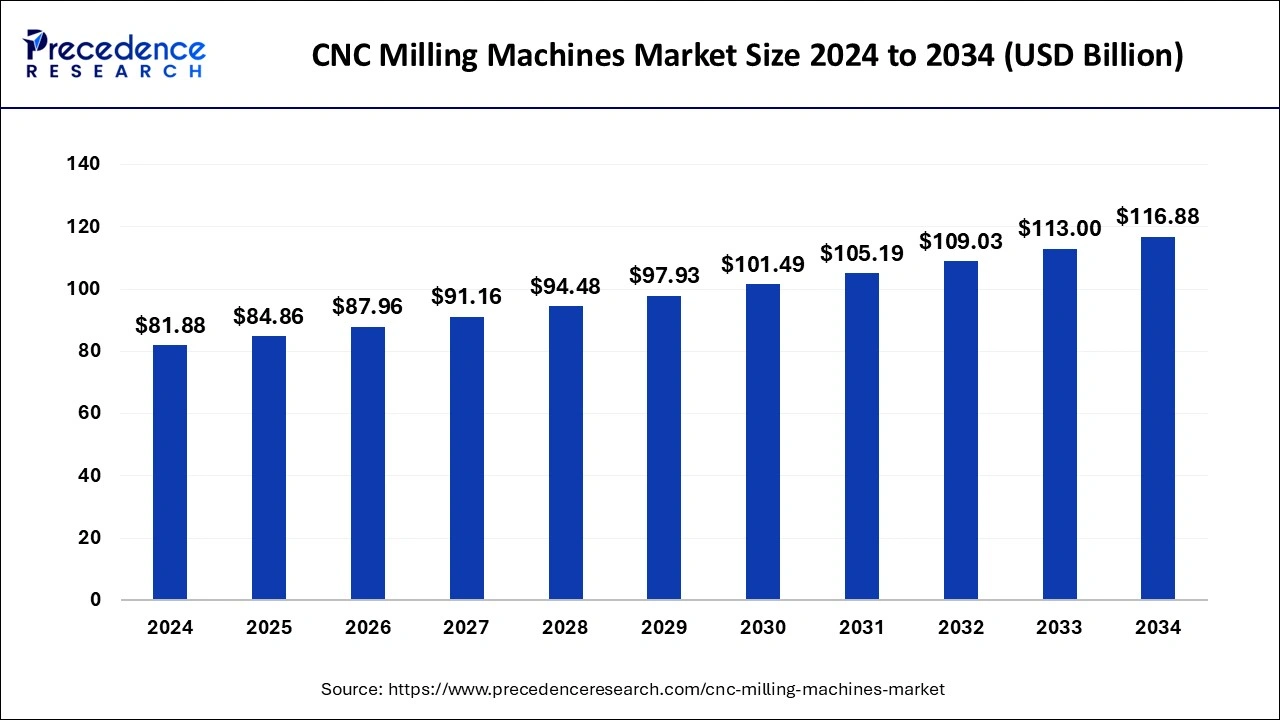

The global CNC milling machines market size reached USD 79 billion in 2023 and is projected to rise to around USD 113 billion by 2033, growing at a CAGR of 3.64% from 2024 to 2033.

Key Points

- Asia-Pacific held a dominant share in the CNC milling machines market in 2023 with 43%.

- Europe will be the fastest growing region during the forecast period.

- According to product type, the vertical CNC milling machines segment dominated the market.

- The universal CNC milling machines segment will show a significant growth rate during the forecast period.

- According to axis type, the 3-axis segment dominated the market and contributed to the largest market share during the forecast period.

- According to end user type, the automotive segment dominated the market and accounted for most of the market share.

- The aerospace and defence segment will have a significant share of market in the forecast period.

The CNC milling machines market has been witnessing steady growth in recent years, driven by advancements in technology, increasing demand from various industries such as automotive, aerospace, electronics, and healthcare, and the growing trend towards automation in manufacturing processes. CNC (Computer Numerical Control) milling machines are versatile tools used for cutting and shaping a wide range of materials, from metals to plastics, with high precision and efficiency. These machines have revolutionized the manufacturing industry by enabling complex designs and rapid production, leading to improved productivity and cost-effectiveness.

Get a Sample: https://www.precedenceresearch.com/sample/4086

Growth Factors:

Several factors contribute to the growth of the CNC milling machines market. One of the primary drivers is the increasing adoption of automation in manufacturing processes to enhance productivity and efficiency. CNC milling machines offer greater precision, repeatability, and speed compared to traditional manual machining methods, making them indispensable tools for modern manufacturing operations. Additionally, advancements in CNC technology, such as the integration of artificial intelligence (AI), machine learning, and Internet of Things (IoT) capabilities, have further fueled market growth by enabling predictive maintenance, real-time monitoring, and optimization of machining processes.

Moreover, the expanding applications of CNC milling machines across various industries have significantly contributed to market growth. Industries such as automotive, aerospace, healthcare, electronics, and defense rely heavily on CNC machining for producing complex components and parts with tight tolerances. The aerospace and automotive sectors, in particular, require high-precision machining solutions for manufacturing lightweight components, engine parts, and structural elements, driving the demand for CNC milling machines.

Furthermore, the growing trend towards additive manufacturing, also known as 3D printing, has complemented the growth of the CNC milling machines market. While 3D printing offers unique advantages in rapid prototyping and customization, CNC milling machines excel in producing high-precision, functional parts with superior surface finish and material properties. As a result, many manufacturers adopt a hybrid approach, combining both additive and subtractive manufacturing techniques to leverage the benefits of each method.

Regional Insights:

The CNC milling machines market exhibits a global presence, with key regional markets including North America, Europe, Asia Pacific, and Rest of the World. North America and Europe dominate the market, owing to the presence of established manufacturing industries, technological advancements, and high adoption rates of CNC machining solutions. Countries such as the United States, Germany, and Japan are major contributors to market growth in these regions.

In Asia Pacific, rapid industrialization, favorable government initiatives, and the emergence of manufacturing hubs in countries like China, India, and South Korea have fueled the demand for CNC milling machines. The region is witnessing significant investments in automotive, aerospace, and electronics sectors, driving the adoption of advanced machining technologies.

CNC Milling Machines Market Scope

| Report Coverage | Details |

| Growth Rate from 2024 to 2033 | CAGR of 3.64% |

| Global Market Size in 2023 | USD 79 Billion |

| Global Market Size in 2024 | USD 81.88 Billion |

| Global Market Size by 2033 | USD 113 Billion |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2033 |

| Segments Covered | By Product Type, By Axis Type, and By End-User |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

CNC Milling Machines Market Dynamics

Drivers:

Several drivers are propelling the growth of the CNC milling machines market. Firstly, the increasing demand for high-precision components across various industries, such as aerospace, automotive, and electronics, is driving the adoption of CNC milling machines. These machines offer unparalleled accuracy and repeatability, making them ideal for producing complex parts with tight tolerances.

Secondly, technological advancements in CNC machining, such as the integration of AI, IoT, and advanced CAD/CAM software, have enhanced the capabilities and efficiency of milling machines. Real-time monitoring, predictive maintenance, and optimization of machining processes have become possible, leading to improved productivity and cost savings for manufacturers.

Furthermore, the growing trend towards automation in manufacturing processes is a significant driver of market growth. CNC milling machines enable automation of repetitive tasks, reducing labor costs, minimizing errors, and increasing production throughput. As manufacturers strive to improve efficiency and remain competitive in the global market, the adoption of CNC machining solutions continues to rise.

Challenges:

Despite the numerous benefits, the CNC milling machines market faces several challenges that may hinder its growth. One of the primary challenges is the high initial investment required for purchasing and installing CNC milling machines. While these machines offer long-term cost savings through improved efficiency and productivity, the upfront capital expenditure can be prohibitive for small and medium-sized enterprises (SMEs) with limited financial resources.

Another challenge is the shortage of skilled labor with expertise in operating and programming CNC milling machines. As these machines become more advanced and complex, there is a growing demand for skilled machinists and engineers capable of optimizing machining processes, troubleshooting technical issues, and maximizing machine utilization. Addressing the skills gap through training programs and educational initiatives is essential for the sustainable growth of the CNC milling machines market.

Additionally, the rapid pace of technological advancements poses a challenge for manufacturers in terms of keeping up with the latest innovations and upgrading their machining capabilities. Continuous investment in research and development is required to stay competitive and meet evolving customer demands for higher precision, faster turnaround times, and greater customization options.

Opportunities:

Despite the challenges, the CNC milling machines market presents several opportunities for growth and expansion. One such opportunity lies in the increasing adoption of Industry 4.0 technologies, which promote the integration of automation, data exchange, and smart manufacturing concepts. By embracing Industry 4.0 principles, manufacturers can optimize their machining processes, improve production efficiency, and gain a competitive edge in the market.

Furthermore, the rising demand for customized and high-value-added components in various industries, such as medical devices, aerospace, and consumer electronics, presents lucrative opportunities for CNC machining companies. As manufacturers seek to differentiate their products and cater to niche markets, the demand for precision machining solutions is expected to increase, driving the growth of the CNC milling machines market.

Moreover, the growing emphasis on sustainability and environmental conservation is creating opportunities for the development of eco-friendly machining solutions. CNC milling machines equipped with energy-efficient motors, recycled materials, and sustainable manufacturing practices can appeal to environmentally conscious customers and contribute to the overall growth of the market.

Read Also: Biopsy Needle Market Size to Reach USD 2.60 Billion by 2033

Recent Developments

- In February 2023, Shilpin Machine Tools Pvt. Ltd, which is a key player in the CNC machine tool manufacturing, organized its 13th exhibition, DIE AND MOULD INDIA 2024. The event was scheduled from 14th February to 17th february, at Bombay Exhibition Center in Goregaon, Mumbai. In this exhibition, the founder and director of Shilpin Machine Tools, Abhay Deshmukh, addressed the challenges that are faced regarding polishing and machining. The event also saw the launch of highly precise machine Acuka.

- In August 2023, CGTech, a leading CNC machine simulation software, announced the launch of their latest version of VERICUT, VERICUT 9.4. It will offer some excellent fatures compared to the old version. CGTech has provided solutions in a wide range of domains, incluuding aerospace, oil and gas, and medical technology. The new version of VERICUT enables the best use of resources. The software has a ToolsUnited interface, which gives access to 40 tool manufacturers, and an improved tool data.

CNC Milling Machines Market Companies

- Doosan

- F-Zimmermann

- DMG MORI SEIKI

- HYUNDAI WIA

- Gleason Corporation

- GF Machining Solutions Management

- Haas Automation

- The CHIRON Group

- GROB-WERKE

Segments covered in the Reports

By Product Type

- Vertical CNC Milling Machines

- Horizontal CNC Milling Machines

- Universal CNC Milling Machines

By Axis Type

- 3-Axis

- 4-Axis

- Others

By End-User

- Automotive

- Electrical and Electronics

- Aerospace and Defense

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.uswebwire.com/