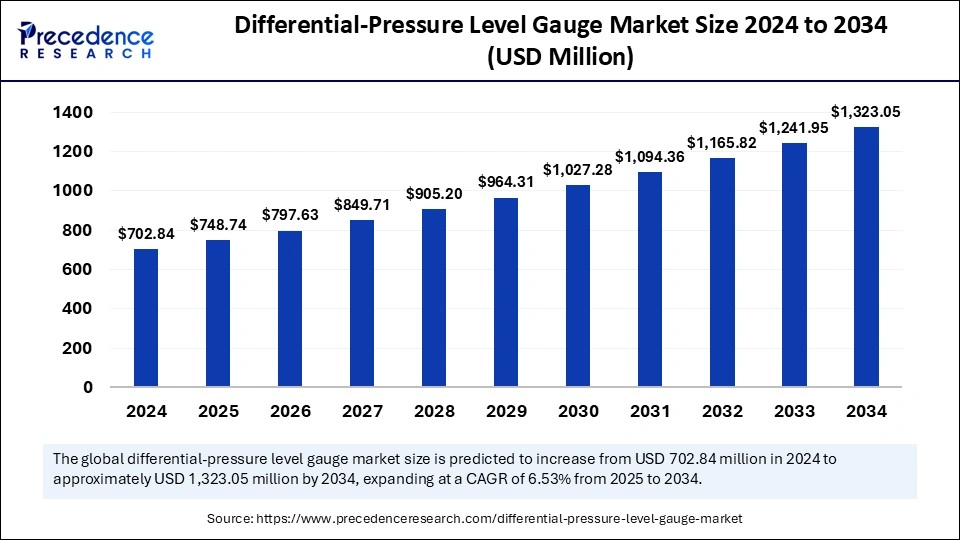

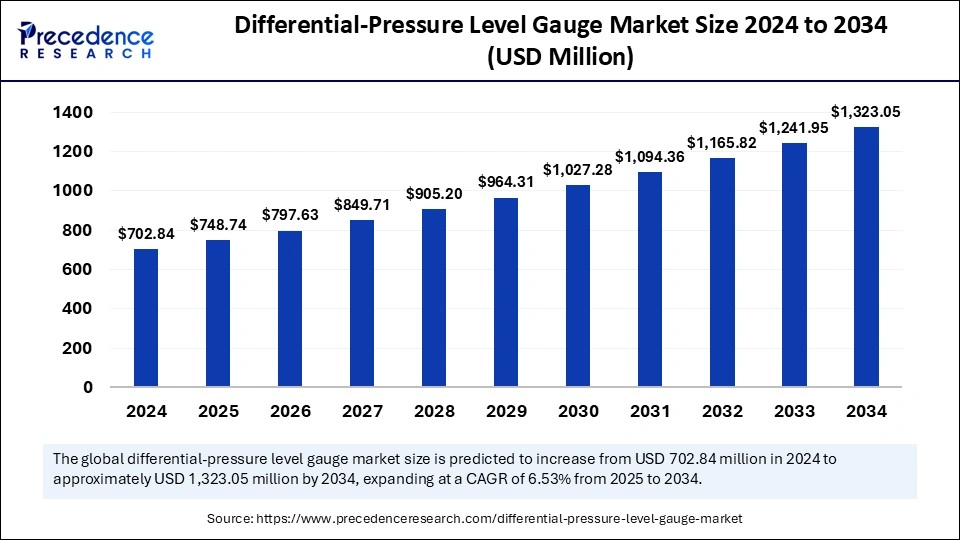

The global differential-pressure level gauge market size is expected to cross around USD 1,323.05 million by 2034 increasing from USD 702.84 million in 2024, growing at a CAGR of 6.53%.

Get a Free Sample Copy of the Report@ https://www.precedenceresearch.com/sample/5760

Differential Pressure Level Gauge Market Key Points

-

In 2024, North America emerged as the dominant market, holding a 34% share.

-

Asia Pacific is expected to witness the highest growth rate from 2025 to 2034.

-

The mechanical differential-pressure gauges segment had the largest market share in 2024.

-

The magnetic differential-pressure gauges segment is forecasted to expand at the highest CAGR over the next decade.

-

The liquid level measurement segment led the market in 2024.

-

The gas level measurement segment is expected to grow at a notable CAGR during the forecast period.

-

The oil and gas sector remained the leading end-use industry in 2024.

-

The food and beverage sector is anticipated to grow the fastest over the projection period.

Differential-Pressure Level Gauge: Overview and Functionality

A differential-pressure (DP) level gauge is a device used to measure the level of liquids or gases in tanks, vessels, and industrial processes. It operates based on the difference in pressure between two points—typically the top and bottom of a tank—to determine the liquid level. These gauges are widely used in industries such as oil and gas, chemical processing, water treatment, and food and beverage.

Working Principle

A DP level gauge measures the pressure difference between two points:

-

The high-pressure side is placed at the bottom of the tank, where the pressure is higher due to the liquid column.

-

The low-pressure side is positioned at the top, where the pressure is lower.

-

The difference between these pressures is used to calculate the liquid level.

Since the pressure is directly related to the height of the liquid column, the gauge provides an accurate level reading, even in sealed or pressurized tanks.

Types of Differential-Pressure Level Gauges

-

Mechanical Differential-Pressure Gauges – These use mechanical components, such as diaphragms, bellows, or bourdon tubes, to display the liquid level. They are durable and commonly used in harsh industrial environments.

-

Electronic Differential-Pressure Gauges – These use electronic sensors and transmitters to convert pressure readings into digital level measurements. They are more advanced and often integrated with industrial automation systems.

-

Magnetic Differential-Pressure Gauges – These gauges use a magnetic coupling mechanism to display level readings without direct contact with the liquid. They are suitable for hazardous or corrosive environments.

Applications of Differential-Pressure Level Gauges

-

Oil and Gas Industry – Used for monitoring liquid levels in storage tanks, separators, and pipelines.

-

Chemical Processing – Helps in maintaining accurate levels in reactors and chemical storage tanks.

-

Water Treatment – Used to measure levels in reservoirs, filtration units, and chemical dosing systems.

-

Food and Beverage – Ensures precise liquid level control in processing tanks and beverage production lines.

Advantages of Differential-Pressure Level Gauges

-

Reliable and Accurate – Provides precise level measurement even in pressurized tanks.

-

Suitable for Various Liquids – Works with corrosive, viscous, and high-temperature fluids.

-

Non-Intrusive Measurement – Magnetic and electronic versions allow level monitoring without direct contact with liquids.

-

Low Maintenance – Mechanical versions require minimal upkeep, making them cost-effective for long-term use.

The role of AI in the differential pressure level gauge market

AI is playing an increasingly vital role in the differential pressure level gauge market by improving accuracy, predictive maintenance, and automation. AI-driven algorithms enhance sensor performance by compensating for fluctuations in liquid density, temperature, and pressure, ensuring more precise level measurements. By integrating machine learning, AI enables real-time data analysis and anomaly detection, allowing industries to optimize processes and reduce manual monitoring efforts.

Furthermore, AI enhances predictive maintenance by analyzing data trends and predicting potential gauge failures before they occur. This reduces downtime and maintenance costs while improving overall system reliability. AI-powered automation also enables seamless integration of differential pressure level gauges with industrial IoT (IIoT) platforms, facilitating remote monitoring and control. As industries shift toward smart manufacturing, AI-driven differential pressure level gauges are expected to become an essential part of process optimization and efficiency.

Differential Pressure Level Gauge Market Overview

The differential pressure level gauge market is expanding due to increasing industrial applications that require precise and reliable level measurement. These gauges play a critical role in maintaining operational efficiency and safety in industries such as oil and gas, chemicals, and water treatment. Technological advancements are further enhancing their performance and accuracy.

Differential Pressure Level Gauge Market Scope

| Report Coverage |

Details |

| Market Size by 2034 |

USD 1,323.05 Million |

| Market Size in 2025 |

USD 748.74 Million |

| Market Size in 2024 |

USD 702.84 Million |

| Market Growth Rate from 2025 to 2034 |

CAGR of 6.53% |

| Dominating Region |

North America |

| Fastest Growing Region |

Asia Pacific |

| Base Year |

2024 |

| Forecast Period |

2025 to 2034 |

| Segments Covered |

Product, Application, End-use Industry and Regions. |

| Regions Covered |

North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Drivers

Rising concerns about safety, process optimization, and environmental sustainability are major drivers of the market. Industries are focusing on reducing human intervention in monitoring processes, leading to increased adoption of automated level measurement solutions. The demand for improved accuracy and efficiency in liquid level measurement further boosts market growth.

Market Opportunities

The emergence of smart sensor technology and AI-driven monitoring solutions is creating significant growth opportunities. The ability to integrate differential pressure level gauges with industrial IoT systems enables remote monitoring and predictive analytics, improving operational efficiency. Moreover, the growing demand for clean water and wastewater management systems is opening new market prospects.

Market Challenges

The high cost of advanced differential pressure level gauges, along with the complexity of installation and calibration, poses challenges for market adoption. Variations in liquid properties, such as density and temperature, can impact measurement accuracy. Additionally, harsh environmental conditions can lead to sensor degradation over time.

Regional Insights

North America leads the market due to its well-established industrial base and strong focus on automation. Asia Pacific is poised for rapid growth as industries expand and adopt advanced measurement technologies. Europe remains a key player due to stringent environmental regulations and the increasing adoption of automation in industrial processes.

Differential-Pressure Level Gauge Market Companies

- Emerson Electric Co.

- ABB Ltd.

- Honeywell International Inc.

- Siemens AG

- Yokogawa Electric Corporation

- Endress+Hauser Group

- Schneider Electric SE

- WIKA Alexander Wiegand SE & Co. KG

- KROHNE Group

- VEGA Grieshaber KG

- Dwyer Instruments, Inc.

- OMEGA Engineering, Inc.

- AMETEK, Inc.

- Ashcroft Inc.

- Fuji Electric Co., Ltd.

- Noshok, Inc.

- SOR Inc.

- Gems Sensors & Controls

- Brooks Instrument, LLC

- ABB Measurement & Analytics

Recent Development

- In July 2024, ABB introduced the PGS300 as its first instrumentation product with an Environmental Product Declaration. This gauge pressure transmitter measures the pressure of liquids, gases, and steam, which is essential for the safety and efficiency of industries like chemicals, oil & gas, and hydrogen.

Segments Covered in the Report

By Product

- Mechanical Differential-pressure Gauges

- Electronic Differential-pressure Gauges

- Magnetic Differential-pressure Gauges

By Application

- Liquid Level Measurement

- Flow Measurement

- Gas Level Measurement

By End-use Industry

- Oil and Gas

- Chemical and Petrochemical

- Water and Wastewater Treatment

- Pharmaceutical

- Food and Beverage

- Power Generation

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Also Read: Biofouling Control Clean Sensor Market

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/