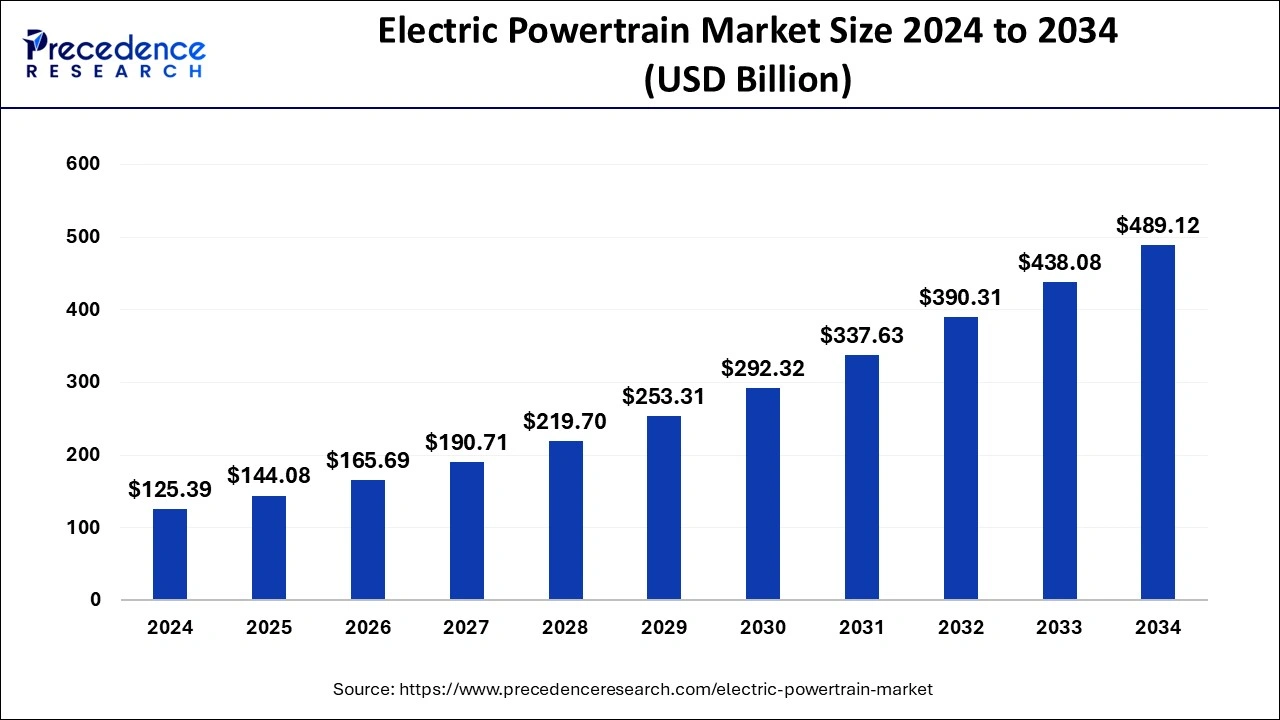

The global electric powertrain market size was evaluated at USD 125.39 billion in 2024 and is expected to surpass around USD 489.12 billion by 2034, with a CAGR of 14.6%.

Key Insights

- In 2024, Asia Pacific captured the highest share of the global market at 61%.

- The BEV segment was the most dominant category in the electric vehicle industry in 2024.

- The battery segment played a crucial role in leading the 5G NTN market by component in 2024.

AI Impact on the Electric Powertrain Market

1. Enhanced Battery Management Systems (BMS)

AI is revolutionizing battery management by improving energy efficiency, safety, and lifespan. Advanced machine learning algorithms analyze real-time data from batteries, optimizing charging and discharging cycles to prevent degradation. AI-driven predictive analytics also help identify potential failures, reducing the risk of battery malfunctions and improving overall performance.

2. Intelligent Energy Optimization

AI enables smart energy distribution in electric powertrains, ensuring optimal power usage between the battery, motor, and other components. By analyzing driving conditions, road gradients, and energy consumption patterns, AI can dynamically adjust power delivery, enhancing vehicle range and efficiency.

3. Predictive Maintenance and Diagnostics

AI-powered predictive maintenance is transforming the electric powertrain industry by reducing unexpected breakdowns. Sensors and AI-driven analytics continuously monitor the health of components such as motors, inverters, and batteries, predicting potential failures before they occur. This proactive approach lowers maintenance costs and improves vehicle reliability.

4. Autonomous and Smart Driving Integration

AI is crucial for integrating electric powertrains with autonomous and semi-autonomous driving systems. AI algorithms optimize acceleration, regenerative braking, and torque distribution based on real-time traffic conditions, improving energy efficiency. This synergy between AI and powertrain technology enhances the driving experience while extending vehicle range.

5. Advanced Motor Control and Efficiency

AI-driven control systems enhance the efficiency of electric motors by optimizing torque distribution and minimizing energy losses. Machine learning models analyze driving behaviors to fine-tune motor performance, ensuring a balance between power output and energy consumption.

6. AI in Powertrain Manufacturing

AI is streamlining production processes by automating quality control, detecting defects, and optimizing supply chains. AI-powered robots ensure precision in assembling electric powertrain components, reducing manufacturing costs and enhancing production efficiency.

7. Real-Time Data Analysis for Performance Improvement

AI collects and analyzes vast amounts of data from electric powertrains, helping automakers fine-tune vehicle performance. This data-driven approach enables continuous software updates, improving vehicle efficiency and responsiveness over time.

8. AI-Optimized Regenerative Braking

AI enhances regenerative braking systems by predicting driver behavior and road conditions, optimizing energy recovery. This improves battery efficiency and extends the vehicle’s range without compromising performance.

9. Challenges and Considerations

Despite its advantages, AI adoption in electric powertrains faces challenges such as high implementation costs, cybersecurity risks, and the need for extensive data processing capabilities. However, as AI technology advances, these challenges are expected to be mitigated.

Market Dynamics

Market Drivers

The electric powertrain market is primarily driven by the growing demand for electric vehicles (EVs) due to increasing environmental concerns and strict emission regulations. Governments worldwide are implementing policies and incentives to encourage EV adoption, further boosting the market.

Advances in battery technology, such as higher energy density and faster charging, are also fueling market growth. Additionally, rising fuel prices and consumer preference for energy-efficient vehicles are pushing automakers to invest in electric powertrain development.

Opportunities

There are significant opportunities in the electric powertrain market, especially with the continuous advancements in battery technology and power electronics. The growing demand for sustainable mobility solutions is leading to innovations in solid-state batteries and wireless charging systems, offering new avenues for market expansion.

Furthermore, the rapid electrification of commercial vehicles, including buses and trucks, presents a lucrative opportunity for manufacturers. Emerging markets in Asia, Latin America, and Africa are also witnessing increased interest in EVs, creating new growth prospects for electric powertrain components.

Challenges

Despite the promising growth, the electric powertrain market faces challenges such as high production costs and supply chain constraints. The reliance on critical raw materials like lithium, cobalt, and nickel makes battery manufacturing expensive and subject to price volatility.

Additionally, the lack of adequate charging infrastructure in many regions hampers widespread EV adoption. Technical challenges, including battery degradation and thermal management issues, also pose significant hurdles for manufacturers and end-users.

Regional Insights

Asia Pacific dominates the electric powertrain market due to the presence of key EV manufacturers and battery suppliers, particularly in China, Japan, and South Korea. The region benefits from strong government support and high consumer adoption rates.

North America and Europe are also witnessing significant growth, driven by stringent emission norms and increasing investments in EV infrastructure. Meanwhile, the Middle East, Africa, and Latin America are gradually adopting electrification trends, although challenges such as infrastructure development and affordability remain.