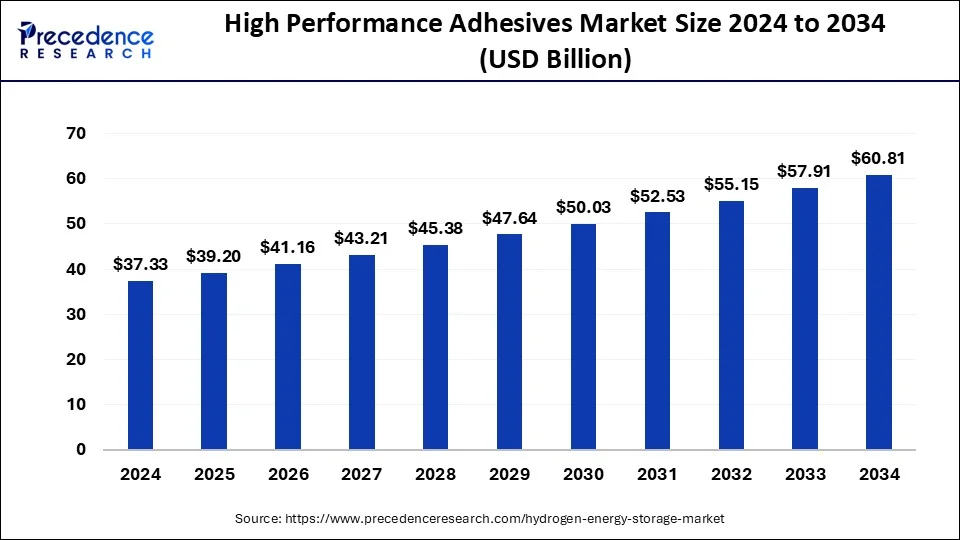

The high performance adhesives market size accounted for USD 37.33 billion in 2024 and is predicted to cross over USD 60.81 billion by 2034 at a CAGR of around 5%.

Get Sample Copy of Report@ https://www.precedenceresearch.com/sample/1073

Key Points

- In 2023, the Asia Pacific region dominated the market, accounting for 44% of the total share.

- Among products, the epoxy segment captured the largest market share.

- Solvent-based technology led the market in terms of revenue in 2023.

- The medical segment is projected to experience the fastest CAGR during the forecast period.

High Performance Adhesives Market: Trends, Growth, and Outlook

The high-performance adhesives market is witnessing significant growth as industries across the globe continue to prioritize advanced bonding solutions to enhance product performance, durability, and sustainability. This surge is driven by several factors including technological advancements in materials, a shift towards lightweight construction, and the increasing demand for eco-friendly solutions. With a market size of USD 37.33 billion in 2024, the global high-performance adhesives industry is expected to reach over USD 60.81 billion by 2034, growing at a robust compound annual growth rate (CAGR) of around 5%. This blog delves into the key drivers, applications, and regional insights surrounding this expanding market.

Introduction to High-Performance Adhesives

High-performance adhesives are specially designed to provide superior bonding capabilities under extreme conditions. They are formulated to withstand high temperatures, aggressive chemicals, intense mechanical stress, and other challenging environments. These adhesives are typically used in sectors where traditional adhesives may fail to deliver the required performance. From automotive and aerospace to construction and electronics, high-performance adhesives play an essential role in ensuring the integrity, longevity, and efficiency of products.

These adhesives are made from advanced materials such as epoxy, polyurethane, cyanoacrylate, and acrylics, which offer superior bonding strength and resistance to environmental stressors. Unlike conventional adhesives, which are typically used for general-purpose applications, high-performance adhesives are designed to meet the rigorous demands of specialized industries.

Key Drivers of the High-Performance Adhesives Market

The growth of the high-performance adhesives market can be attributed to several key drivers:

1. Technological Advancements in Materials

As industries evolve, there is a growing need for more robust and durable adhesives. Technological advancements in materials science have led to the development of adhesives that offer better bonding strength, flexibility, and resistance to high temperatures and chemicals. Innovations such as the introduction of nanotechnology and hybrid adhesives (blending multiple materials) have further enhanced the performance characteristics of these adhesives, making them suitable for a wide range of demanding applications.

2. Demand for Lightweight Materials in Automotive and Aerospace Industries

The automotive and aerospace sectors are increasingly focused on reducing the weight of their vehicles and aircraft to improve fuel efficiency and reduce emissions. High-performance adhesives have become indispensable in these industries as they allow manufacturers to bond lightweight materials such as aluminum, composites, and plastics. Adhesives provide a means of bonding these materials without compromising their structural integrity or performance.

In the automotive sector, high-performance adhesives are used in body panels, window bonding, and interior components, among other applications. Similarly, in the aerospace sector, adhesives are used for critical components such as fuselage assembly, interior fittings, and engine components.

3. Growing Demand for Eco-Friendly Solutions

Sustainability has become a major focus across industries. Consumers and manufacturers alike are increasingly looking for eco-friendly alternatives that reduce environmental impact. High-performance adhesives are often more sustainable than traditional mechanical fasteners such as screws, nails, or bolts. They provide a cleaner, more efficient bonding solution that eliminates the need for drilling, welding, or other energy-intensive processes. Moreover, many high-performance adhesives are now being developed with bio-based or recyclable materials, further enhancing their sustainability credentials.

4. Increasing Focus on Automation and Efficiency in Manufacturing

In sectors such as electronics, automotive, and construction, the need for automation and efficient manufacturing processes is more important than ever. High-performance adhesives play a crucial role in facilitating automation in these industries. For example, in electronics manufacturing, adhesives are used to bond components during automated assembly processes, ensuring a strong bond without the need for manual intervention. Similarly, in automotive manufacturing, adhesives are used to bond parts during automated production lines, streamlining the assembly process and reducing production time.

Applications of High-Performance Adhesives

The high-performance adhesives market spans a variety of industries, each with unique requirements for bonding solutions. The following are some of the key sectors driving demand for high-performance adhesives:

1. Automotive Industry

In the automotive sector, high-performance adhesives are used to bond a wide range of materials, including metals, composites, plastics, and glass. These adhesives are critical for lightweighting vehicles, enhancing fuel efficiency, and improving safety. They are used in applications such as bonding windshields, exterior panels, interior components, and structural parts.

High-performance adhesives are also playing a significant role in the development of electric vehicles (EVs). EV manufacturers rely on adhesives for bonding battery packs, electric motors, and other sensitive components while ensuring the structural integrity of the vehicle.

2. Aerospace and Aviation

The aerospace industry has some of the most demanding requirements for adhesives, as components need to withstand extreme conditions such as high altitudes, temperature fluctuations, and mechanical stress. High-performance adhesives are used extensively in aircraft assembly for bonding materials like carbon fiber, aluminum, and composites. They are used in the production of wings, fuselages, interiors, and engine components, contributing to weight reduction, increased durability, and improved fuel efficiency.

3. Electronics and Electrical Industry

The electronics industry is a major consumer of high-performance adhesives, particularly for bonding delicate components such as semiconductors, sensors, and displays. These adhesives are used in applications such as printed circuit boards (PCBs), mobile phones, computers, and consumer electronics. The need for lightweight, durable, and heat-resistant adhesives in electronic devices is driving the demand for high-performance adhesives in this sector.

4. Construction and Building

High-performance adhesives are also increasingly used in the construction and building industry, where they are employed for bonding tiles, flooring, insulation materials, and other structural components. These adhesives are especially useful for applications that require long-lasting performance in harsh environmental conditions, such as in areas with high humidity or extreme temperatures. Additionally, adhesives are becoming increasingly popular in energy-efficient building designs, as they help reduce the need for traditional mechanical fasteners and reduce the overall weight of structures.

5. Medical and Healthcare

The medical industry is another key sector where high-performance adhesives are in demand. These adhesives are used for bonding medical devices, wound dressings, surgical instruments, and implants. For example, in the production of medical devices such as catheters or pacemakers, high-performance adhesives are used to provide a secure, durable bond while minimizing the risk of contamination or irritation. The need for biocompatibility and sterilization resistance is also a major consideration in the selection of adhesives for medical applications.

Regional Market Insights

The global high-performance adhesives market is witnessing significant growth across various regions, driven by increasing industrialization, technological advancements, and the demand for efficient bonding solutions. Let’s look at the key regions contributing to the market growth.

North America

North America is one of the largest markets for high-performance adhesives, driven primarily by the automotive, aerospace, and electronics sectors. The region’s robust manufacturing base, coupled with the growing demand for lightweight materials and eco-friendly solutions, has fueled the adoption of high-performance adhesives. The presence of key market players in the U.S. further drives the region’s market growth.

Europe

Europe is another major region for the high-performance adhesives market, with strong demand from automotive, aerospace, and construction industries. The European Union’s stringent regulations on emissions and sustainability have accelerated the adoption of high-performance adhesives, particularly in automotive and building applications. The growing shift towards electric vehicles in Europe also presents new opportunities for adhesive manufacturers.

Asia-Pacific

The Asia-Pacific region is expected to witness the fastest growth in the high-performance adhesives market due to the rapid industrialization and growing manufacturing sectors in countries like China, India, and Japan. The automotive and electronics industries in the region are major consumers of high-performance adhesives. Furthermore, the rising adoption of electric vehicles and the expanding infrastructure in developing countries are expected to drive market growth in this region.

Latin America and Middle East & Africa

While these regions currently represent a smaller share of the global high-performance adhesives market, they are poised for significant growth in the coming years. As industrialization continues in Latin America and infrastructure development accelerates in the Middle East and Africa, the demand for high-performance adhesives is expected to increase in construction, automotive, and aerospace applications.

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/